SPM Solutions

Auto Tread Weighing and Rejection System:

- In this machine, Tyre treads comes on a conveyor and passes through a weighing scale. If the weight of the tread is not in the allowed weight range in the PLC program, then that tread will be sprayed with red color with a spray placed on the conveyor after the weighing scale. The red spray shows the rejected tread and that will be removed from the conveyor.

Color Detection System:

- In this machine, sodium pieces comes on a conveyor and passes through a color sensor placed on a conveyor. The color sensor passes all the pieces with the color which is defined in the PLC program. The pieces which are not of the defined color are rejected through an air jet placed after the color sensor on the same conveyor.

Oil batching and transfer:

- In this machine, Oil is filled in a holding tank through 2 valves. This tank is placed on a load cell, which is connected to PLC as an Analog input. Once the tank is filled and the weight of the oil is in the allowed range, then the discharge valve is opened which is placed at the bottom of the tank and the oil is taken away for further use, based upon request received from upstream system, once emptied, next batch is kept ready waiting for request from upstream system.

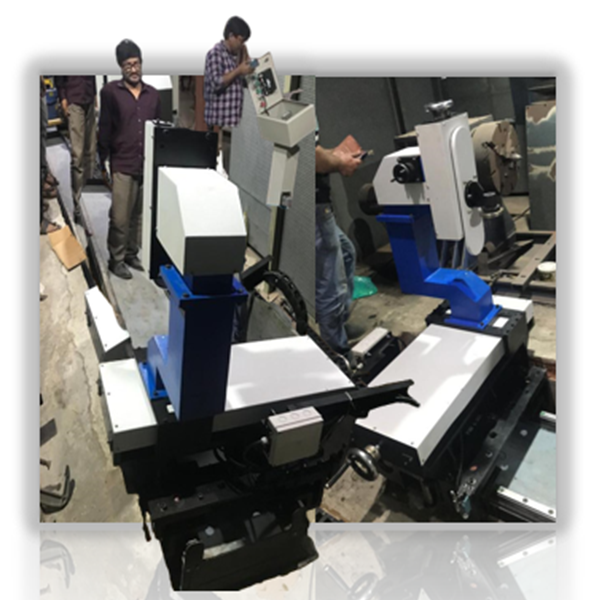

Depacker Machine DP1000

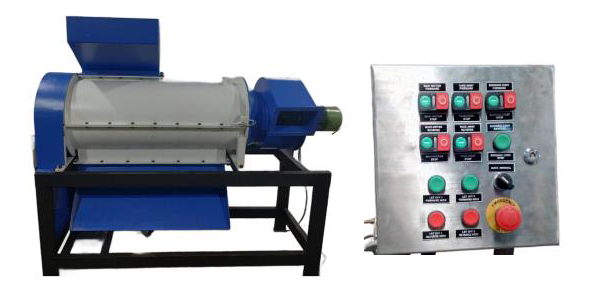

Aggitate Mixer For Pharma/Food/Chemical

Heat Tracing System